Multi-purpose insulated panels for temperature controlled applications

Thermocore insulated wall and ceiling panels provide hygienic and temperature-controlled systems for cleanroom and cold store projects in applications such as food preparation, pharmaceutical and temperature-controlled storage. Thermocore meets optimum levels of air leakage and thermal performance for the most challenging conditions. Available with a range of accessories to compliment the panel systems, Thermocore can be installed vertically or horizontally with door and window integration options meeting the highest specification.

Why choose Thermocore?

Non-combustible panels

Manufactured to ISO 9001:2015

Suitable for industrial environments

Designed for low temperatures

Good shear with tensile strength

Thermocore – at a glance

Dimensions

Width – Standard width of 1190mm. Can be manufactured from 900mm depending on quantity required.

Length – Manufactured to any length, only restrictions being transportation. Rebates and core cuts available on request.

Core

Thermocore insulated composite panels have a Polyisocyanurate core. Manufactured from MDI Polyols and blowing agent (ODP Zero + GWP less than 5) to produce highly crosslinked polymers. This closed cell foam has an excellent thermal performance, good shear and tensile strength and is very lightweight.

Quality assured

The panels are manufactured to an ISO 9001 quality assurance system.

Our Thermocore products

Thermocore FAQs

What is the panel density?

Thermocore panels have a density of 40kg fully cured sanded and de-dusted, extremely square and flat full boards of specified thickness.

What are the panel joint details?

Thermocore panels can be installed using both the Intaloc and Secret Fix joint details.

What profiles are available?

Flat: Laminated panel produces a much flatter surface than other manufacturing methods, but ‘optical’ flatness is not assured; some shadowing may be evident in certain lighting situations.

V-Rib: Pitch 200mm – 5 per panel

Castellation: Pitch 100mm

Micro-rib: Pitch 30mm – 1 side only

What are the fire ratings & maximum recommended span (m)?

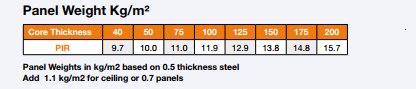

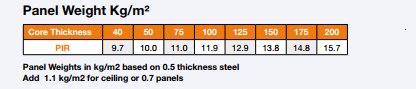

What is the panel weight?

What are the thermal properties?